The Imp

Potted History of the Hillman Imp

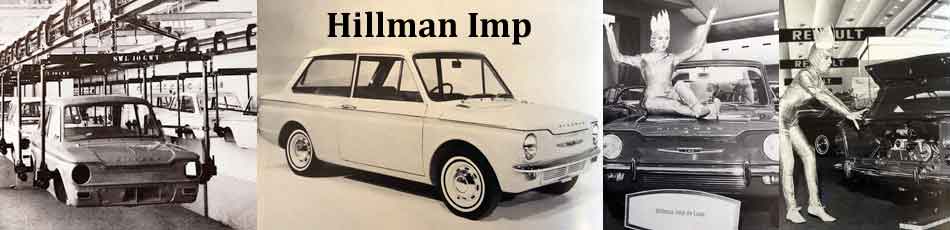

The Hillman Imp is a compact, rear-engined saloon car that was manufactured under the Hillman marque by the Rootes Group (later Chrysler Europe) from 1963 to 1976.

Known internally within Rootes as the “Apex” project, the Imp was to be the first post-Second World War small car by the Rootes group. Its main rival on the home market was the BMC Mini which preceded the Imp by nearly four years. One key difference between the two cars was the Imp’s 875 cc all-aluminium power unit, adapted by Rootes from a Coventry Climax FWMA fire pump engine which had enjoyed some success on the racing scene. However the engine used for the Imp differed considerably from the original Climax engine, for instance having an entirely different cylinder head.

The Imp’s engine was mounted behind the rear wheels, slanted over at 45° to fit. This was done to keep the centre of gravity low and to minimise its effects on the roadholding of the car. Rear-engined cars generally suffer from oversteer handling characteristics to some extent, and to counteract this as much as possible the Imp had a semi-trailing arm independent rear suspension system. This relatively costly and sophisticated solution which was atypical for small car design at the time was insisted upon by its designers after testing at length a Chevrolet Corvair with swing axles. Unusually, to attain balanced handling, the Imp actually used swing axle geometry at the front, however this initially led to too much understeer and the camber was later reduced by lowering the pivot points.Rootes relied upon a team led by two young designers, Tim Fry and Mike Parkes who were given an almost free hand to come up with a small car that would fit well into the Rootes car programme. This at the time centred on derivatives of the Hillman Minx car.

Over the life of the car, Rootes (and later Chrysler UK) produced three basic body styles. The original Saloon was introduced in May 1963 and ran through to the end of production in 1976. It had an opening rear window, making it effectively a hatchback. The opening rear window was intended to make it easier to load the small luggage area behind the fold-down rear seat squab (the fold-down nature of the rear seat was itself unusual in small car design at the time, it being more usually associated with larger more upmarket estate cars). In 1965 a van was introduced which was badged as Commer Imp. The van’s pressings were later used to create an estate, badged as a Hillman Husky, which came out in 1967. Several prototypes of estate car using the saloon type car with extended rooflines were tried, but perhaps unwisely never offered to the public. Instead buyers choosing the estate had to live with a van-derived car with somewhat uneasy styling. Both the van and estate ceased production in 1970.

In an attempt to interest a wider public when sales figures fell well short of the intended 100,000 or more cars per annum, some badge-engineered derivatives, such as the luxury Singer Chamois (launched October 1964), and the Sunbeam Sport (launched October 1966) with a more powerful twin-carburettor engine were on offer with various degrees of success. For marketing reasons in many export markets Imps were sold as Sunbeams.

In 1967 a coupe was introduced, badged as the Imp Californian. The coupe bodyshell was broadly similar to the standard body but featured a more steeply raked windscreen and rear window which, unlike that on the standard bodied cars, could not be opened. Much to the disappointment of the designers the somewhat faster looks did not translate into better acceleration and top speed figures. In fact aerodynamics of the standard saloon are slightly better. A more luxurious version, the Singer Chamois Coupe, was then introduced and the final coupe version, the more sporty Sunbeam Stiletto, made its appearance at the Paris Motor Show in October 1967.

The Imp was a massive and expensive leap of faith for Rootes. The company did not have any recent experience building small cars, even though it started off as a car builder by offering the then small Hillman Minx back in 1931. However the Minx had since grown larger and larger, and by the time the Imp was introduced it was well established as a medium-size family car. For the Imp, Rootes pioneered the use of an aluminium engine in a mass production car. However this process proved to be rather more complicated than simply substituting a well known and trusted cast iron design with a new aluminium design. Rootes had to build a new computerised assembly plant on the outskirts of Glasgow, in the town of Linwood in which to assemble the Imp, since planning regulations banned it from further expanding its Ryton plant near Coventry. Government grant money, was offered to bring jobs (approx 6000) to this unemployment blackspot, which had suffered many redundancies in the declining shipbuilding industry on the banks of the river Clyde. The investment also included an advanced die-casting plant to manufacture the aluminium engine casings, and a stake in a brand new Pressed Steel Company motor pressings works which manufactured all the new car’s body panels. One of the many problems was that Linwood was over 300 miles (480 km) away from Ryton, and the engine castings although made in Linwood, would have to be sent to Ryton to be machined and assembled, and then sent back up to be put on the cars – a 600-mile (970 km) round trip. In the end a complex schedule of trains shifting completed cars and raw castings down south and trains loaded with engine – gearbox assemblies and many other Ryton sourced goods ran north for the duration of Linwood Imp production.

Glaswegian workforce, who were mainly recruited from the shipbuilding industry were not versed in the intricacies of motor vehicle assembly, and Imp build quality and reliability suffered accordingly. Industrial disputes and strike action were commonplace. In 1964 there were 31 stoppages and only a third of the plant capacity was realised – 50,000 rather than 150,000. On the other hand the Imp was seen as a “Scottish car” and was popular north of the border. Later the Imp was allowed to evolve from a revolutionary new car intended for Rootes customers who intended to buy their wives a second car, a quality small car with some above average features at that, into a kind of ultra cheap car with cheaply, even some poorly executed, design features on offer as a kind of British Skoda. At one point the basic Hillman Imp was the cheapest new car on the British market, which temporarily pushed up rather sluggish sales figures.

The daring design of the Imp was underdeveloped, due in part to the government timetable to start production. Mechanical and cooling system problems were commonplace in the early cars. In 1966 a major revision of the Imp was released, effectively splitting the marque into Mk I and Mk II cars. The Mk I Imps had a pneumatic throttle linkage and automatic choke, both of which were replaced by more conventional items on the Mk II. The Mk II also had improved front suspension geometry and a host of trim and detail changes. Although the car was constantly improved over its life there was no single change as big as that in 1966.

A further upgrade took place in 1968, however: the driver was now confronted with a revised instrument panel and steering wheel.The large speedometer previously at the centre of the view through the steering wheel was replaced by a horizontal row of four circular dials/displays of varying detail and complexity according to the model specified. The right hand dial, the speedometer, was now to one side of the driver’s normal sightline, while one multi-functional stalk sticking out from the right side of the steering column replaced the two less ambitiously tasked control stalks that in the earlier cars had sat directly behind the steering wheel, one on each side.The earlier Imp had won plaudits for the ergonomic excellence of its dash-board / fascia, and the replacement of it reflected similar trends apparent in several new and modified UK models at the time, undertaken in the name of “production rationalization”: on the Imp the more modern arrangement was seen by some as a missed opportunity.

The initial problems damaged the Imp’s reputation and popularity tailed off, with half of all production being from the first three years. It still sold thanks to its competitive price, distinctive styling and cheap running costs, but sales never lived up to expectations for what had become a very competent small car. Another problem that contributed to the reputation of poor reliability, was the lack of understanding of the maintenance needs of alloy engines by owners and the motor trade in the 1960s. It was overshadowed in popularity by the Mini. Although the Mini initially sold poorly, by the mid ’60s it was the ‘in’ thing to have, whereas the Imp never enjoyed such status as a fashion statement.

The huge investment in both the Imp and the Linwood production plant proved to be one of the reasons for the undoing of Rootes Group, and its commercial failure fuelled the huge losses suffered although the main reason for Rootes Group losses were industrial unrest and the effects of the forthcoming cooperation with Chrysler Corporation of the USA. Initiated by Lord William Rootes in 1964 as a partnership, the signs were soon on the wall. Lord Rootes died in October and soon afterwards the deal began to take a turn for the worse from a Rootes point of view. By 1967 the company had been acquired by Chrysler, to become part of Chrysler Europe, long after, to be overshadowed by the French Simca. A year later, ahead of the 1968 London Motor Show, the recommended retail prices of most Imp models were reduced for the domestic market by more than 4%, despite the general price inflation affecting the UK. Chrysler stewardship was blamed by some for the demise of the Imp in March 1976, after fewer than 500,000 had been built and the entire empire collapsed two years later, when it became part of Peugeot. The Linwood plant was closed in 1981.

Production & Export

Approximately half a million, 50% of those in the first 3 years of production. Unassembled cars were exported for assembly in Ireland, New Zealand, Portugal, Venezuela, Uruguay, Costa Rica, South Africa and Australia.